1) What is the make and model of your machine?

2) How many shoes does this model have?

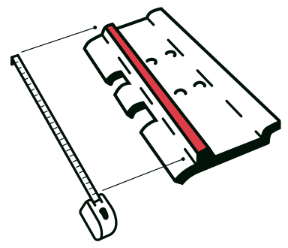

3) What is the with of the track shoe?

4) What is the thickness at the top of the worn grouser?

5) What is the height of the worn grouser?

6) What is the total desired height?

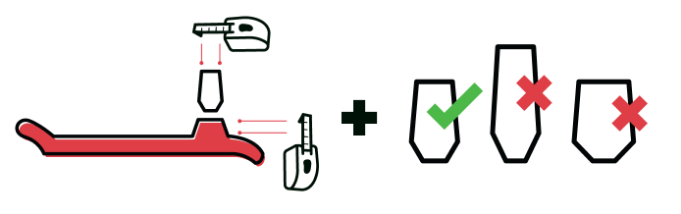

Profile Chart

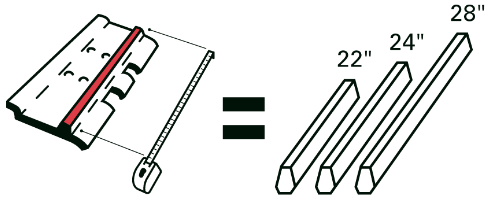

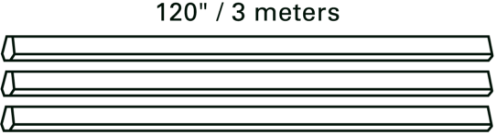

Option 1: Cut-To-Length Bar

Do you want Cut-to-Length Bar?

Using the measurements taken in Step One, you can order bar custom cut to your needs.

ADVANTAGES OF WELD-READY™ CUT-TO-LENGTH BAR

- Bar arrives ready to weld, straight from the box.

- Straight, curved, forged, and beveled bar available for a variety of wear patterns, eliminating the need to trim.

- The bar is cut BEFORE heat treating. Cutting the bar after heat treating takes hardness out of the bar on cut ends.

- No wasted labor, sharp edges, scrap, time and hardness loss associated with cutting the bar on your own.

- Dura-Tuff’s premium Dura-Packed Shrinkwrap protects packaging during shipping and storage and ensures it arrives in tact

Option 2: Full-Length Bar

OR, do you want Full Length Bar?

When you purchase Full Length Bar, you can cut them down to your preference

REASONS/ADVANTAGES OF FULL LENGTH (10 FOOT) BAR

- Full Length or 10 Foot Bars are a great option to maintain inventory.

- Having bar in stock allows dealers to make bar available to their customers anytime.

- Customer can cut bar down for regrousering, ice lugs, and other abrasive applications such as bucket and shovel reinforcement.

- Dura-Tuff offers bundle pricing discounts for dealers who want to stock full length bars.

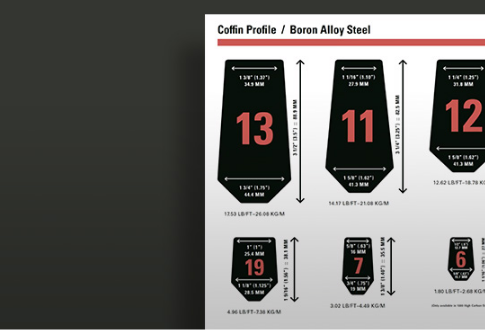

HARDNESS PROFILE

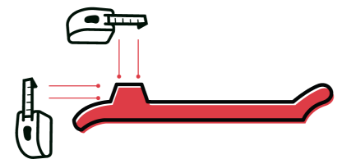

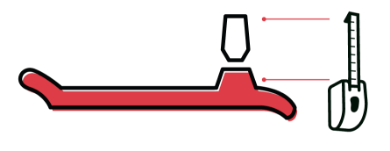

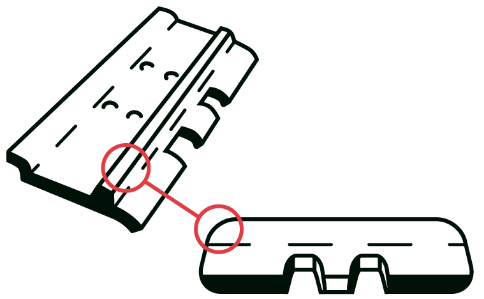

What is a wear pattern?

Depending on the impact of and abrasiveness of the environment, the worn grouser can take on several wear patterns. Selecting the right shape to fit the wear pattern can eliminate trimming, which saves time, money, and improves overall performance in the field.

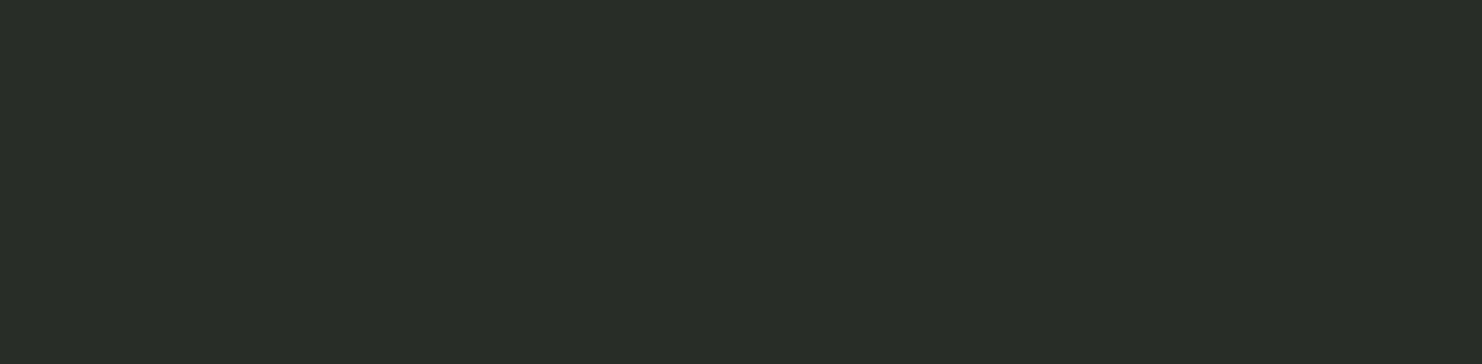

Which Shape Best Fits Your Wear Pattern?

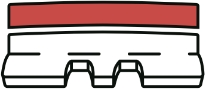

Straight Bar

- Wear pattern is even all the way across

- Shoe is trimmed for a flat surface

- Works well with automated welders

Forged Bar

- Rounded wear pattern with severely worn edges

- Eliminates the need for trimming

- Ends of bar are clipped at a 45 degree angle for less turning resistence and added support

- Hooked bar ends are designed to fit track shoes with severe wear on edges

- Ideal for track shoes welded in the field

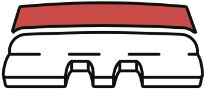

Curved Bar

- Wear pattern is even all the way across

- Slightly rounded wear pattern

- Eliminates the need for trimming

- Curved bar shape reduces amount of fill weld required

- Ideal for track shoes welded in the field

- Works well with automated welders

Beveled Bar

- Wear pattern is even all the way across

- Shoe is trimmed for a flat surface

- Ends of bar are clipped at a 45 degree angle for less turning resistance and added support

- Works well with automated welders