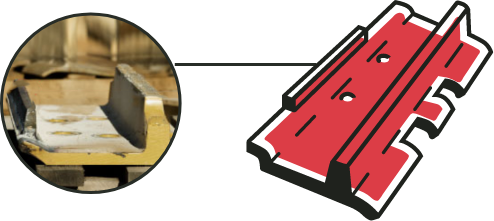

Trailing Edge Bar (T-Bar)

Trailing Edge Bar (T-Bar) is an additional, smaller grouser bar, welded on to the trailing edge of the track shoe. The T-Bar absorbs the bulk of the wear and keeps the track shoe thick enough to allow the same shoe to be regrousered multiple times. T-Bar is the perfect solution to prolonging track shoe life and increasing undercarriage savings by as much as $10,000 per machine.

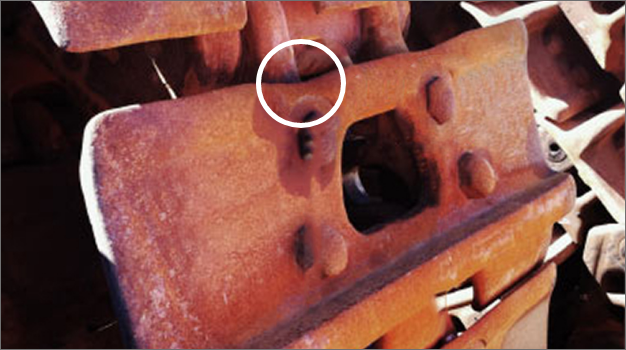

Protect Your Hardware

Trailing Edge Bar, also called Bolt Relief Bar provides protection to the track shoe hardware. Bolt heads often become overly worn and need to be torched off. By installing trailing edge bar, track shoe hardware can be removed and re-used for another maintenance cycle.

DID YOU KNOW?

The hardware on a large dozer can cost as much as $5,000! Trailing Edge Bar is only a fraction of that cost. It has become a standard practice for many of the world’s largest dozer fleets and undercarriage track shops.

Helpful Hint

Trailing Edge Bar is commonly welded onto a brand new track shoe in order to protect the shoe from the get go. It is usually not necessary to replace the Trailing Edge Bar during the life of the shoe, but it extends the shoe life significantly. When you need grouser trackpads, excavator track shoes, bulldozer trackpads, excavator ice lugs, or bolts for grouser bars and ice lugs, Dura-Tuff has exactly what you need. We also handle dozer track repair.

Without T-bar, Shoes Develop An Uneven Trailing Edge Scalloping Effect, Bolt Heads Wear Down, And The Overall Shoe Becomes Thin And Frail.

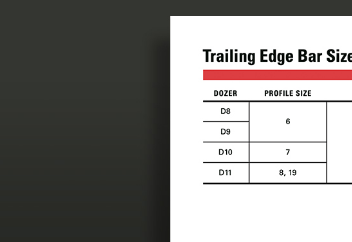

Trailing edge sizes

Common applications

Full Width T-Bar welded across the entire trailing edge of the track shoe.

Centered T-Bar welded in the center of the trailing edge.

Centered T-Bar with tungsten carbide overlay for additional wear life.